|

|

Adding LED Lighting To Generator Shed

|

We live in hurricane prone central Florida.

Power outages are common. Sometimes due to a major storm,

sometimes due to a lightning strike. All part of the price of

living in paradise. |

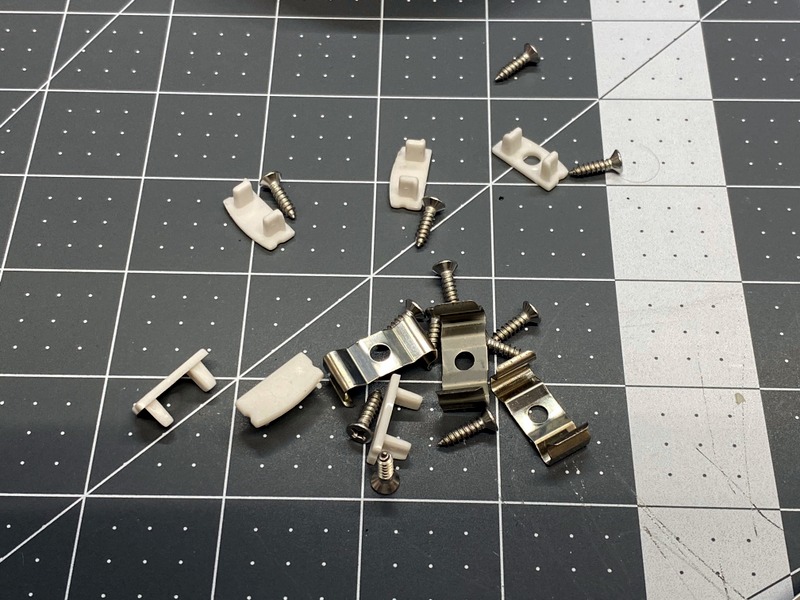

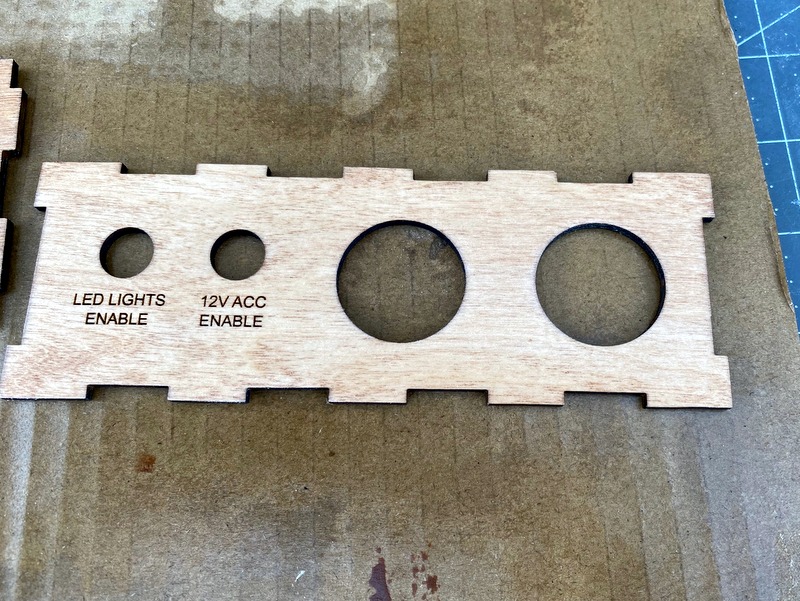

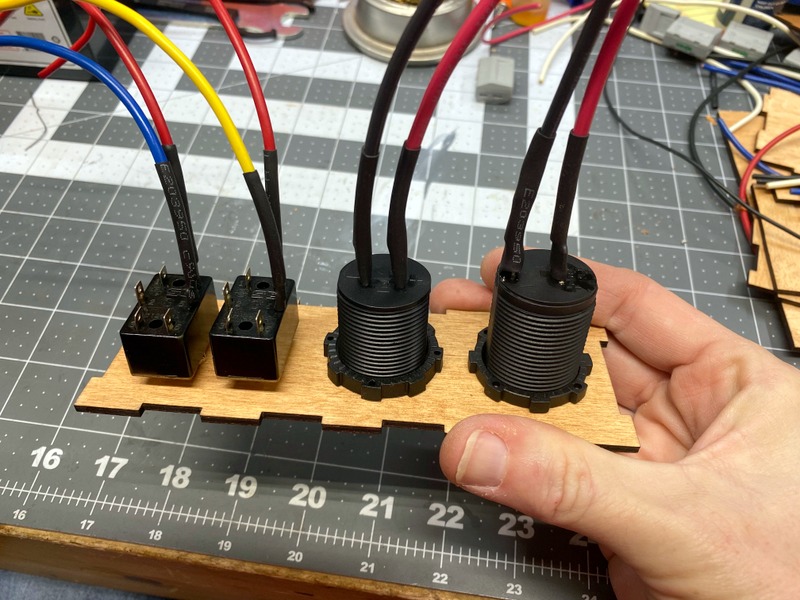

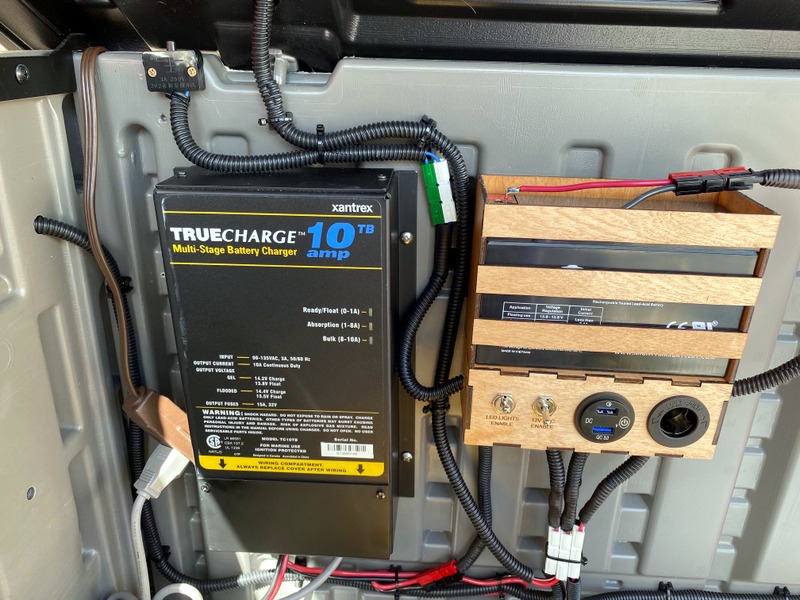

| I could have simply wired the battery to the LEDs and the switch, but I have a bunch of spare components from other projects laying around. I wanted the ability to turn off the lights during the day, or during extended outages. I also wanted the ability to recharge cell phones, or run other 12V appliances. I added a second switch to turn those off when not needed to avoid any parasitic loads. The SVG files are located at the bottom of this page if you have access to a laser cutter, or 3D printer. I made these from 3mm thick Baltic Birch plywood. The wood was stained, clear coated, and assembled with epoxy. The bottom plate is screwed in place in case I need access in the future. The text under the switches is laser engraved. Details on the storage box are here. |

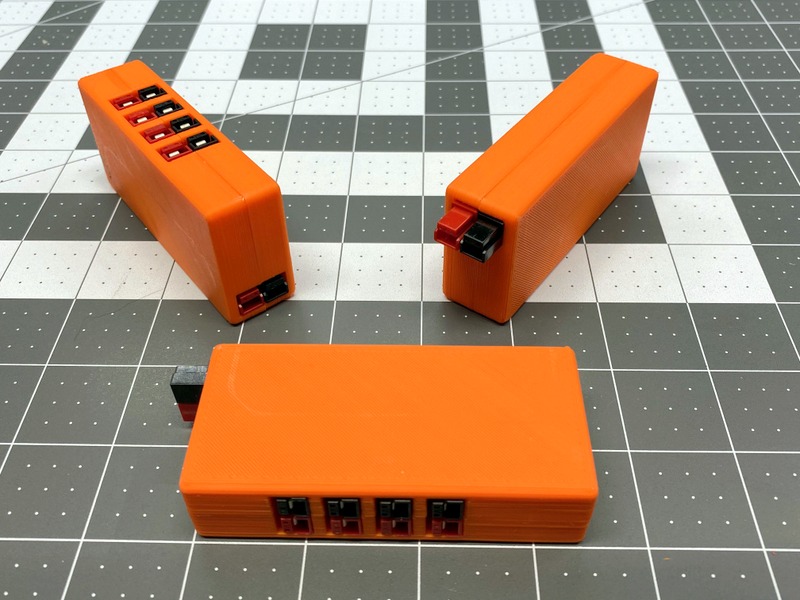

The Battery Box And Control Center

After a few mods to prototypes, I was finally satisfied with the design. The parts don't take long to cut out with a K40 laser. I used a gel stain to prevent uneven color. |

The laser engraved text is already dark, and didn't require any further attention. |

I wanted to box to be as small as possible, so the 12V 7AH battery determined the width. I dug through my parts bins, and found useful components to utilize the available space. |

Man, using CAD software to layout the holes, and a laser to cut them, is FAR easier than the old methods I used in the past! I soldered wires to the terminals, but Fast On connectors would have worked as well. |

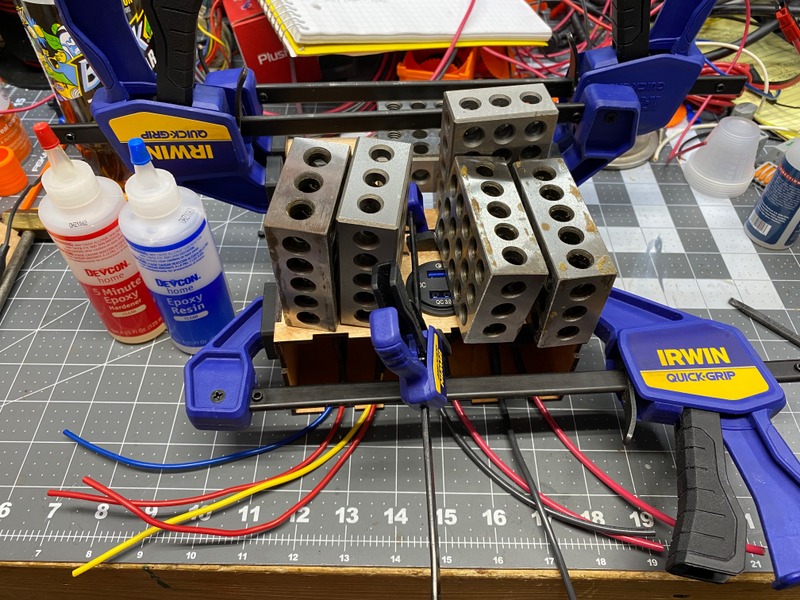

I typically use a cyanoacrylic adhesive to assemble laser cut boxes, but I used epoxy due to the weight of the battery. |

I used a number of 1-2-3 machinist's blocks to hold the control panel in place while the adhesive set. |

In the past, I would have either soldered all the connections, or used a barrier strip. Now I tend to use Wago lever nuts. These work great for connecting different sized wire conductors, either stranded, wire or solid. |

This is just before the bottom plate was screwed into place. Since it's not glued into place, I can easily access the inside if ever needed. I also put connectors on all connections, making removal or changes, very quick and easy. |

All wired up, and ready for use. The long cable on the left side connects to the generator battery to keep it charged. |

A close-up of the door switch, battery charger, and control box. |

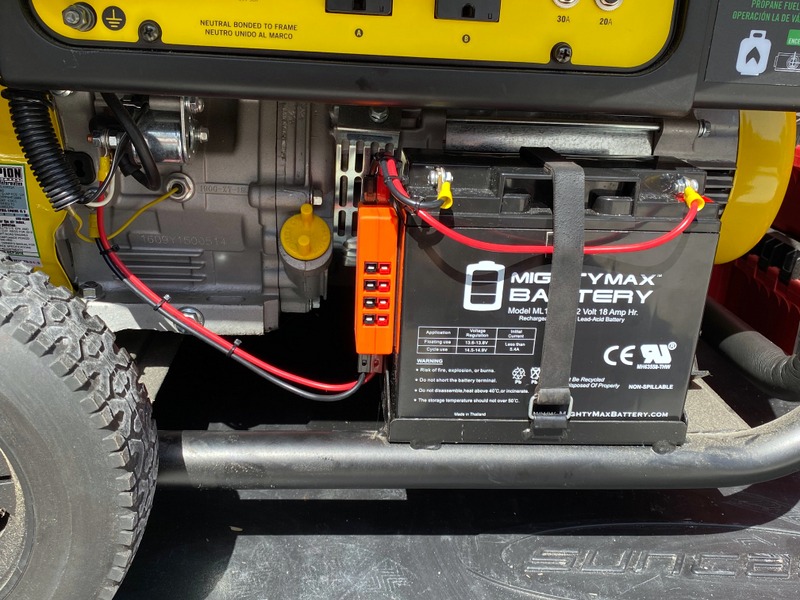

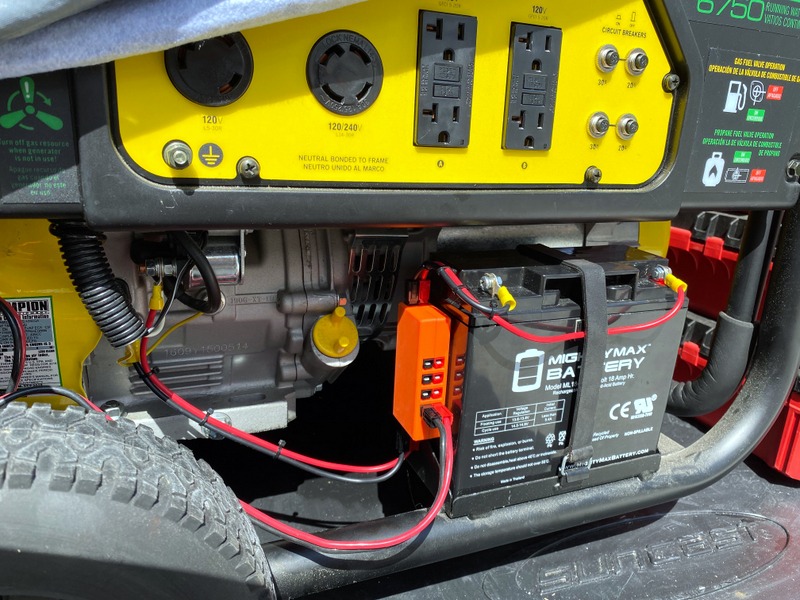

I removed the generator battery to modify it. |

I 3D printed Anderson PowerPole power distribution boxes. The connectors are put inside, and the pins soldered together. The 3D files are located here - LINK. |

The distribution box was attached to the battery with a piece of 3M VHB tape. |

The battery can be removed from the generator, and used as a stand-alone power source for 12V lighting, HAM radio gear, etc. |

The battery plugs into the top connector, the generator connects to the bottom. |

The charging cord was plugged into one of the front connectors, and is unplugged when the generator is deployed. |

| Here are the SVG files if you decide you'd like

to make your own battery tray and control center: Top & Bottom Front Back Side No Hole Side With Hole Cross Braces |

These are the products I used for this project, or are recommended:

As an Amazon Associate I earn from qualifying purchases.

|

Last updated 02/22/22 All rights reserved. |