I've enjoyed woodworking for most of my life.

It usually involves noisy equipment, and makes a huge mess. Also,

the accuracy depends on the materials used, the tools, the setup, the

jig, the user's skill, and most importantly, luck. Once the human

element is mostly removed, the quality of the work greatly increases!

The very common K40 type laser is very popular, for good reason.

As they come, they are lacking basic safety features, and have a limited

work area. With some simple mods, this thing can be a workhorse.

You could buy a Glow Forge, which is a nice, ready to use package.

But it has some major downsides. It's very expensive. The

software is proprietary, and is web based. If the network is down,

or they go out of business, you might have a paperweight. There

are also no options for upgrades, such as a larger/more powerful laser

tube, or a rotisserie for engraving cups/mugs.

K40 lasers start around $400 on eBay, but lack a warranty, and require

more tinkering to get started. I bought an Omtech brand from

Amazon. It came almost ready to run. The laser had been

tested, the mirrors aligned, LED lighting inside the box, and a laser

pointer to show where the cut will be made. The actual laser beam

is invisible

It does need some mods, and I recommend adding a few optional ones.

I'll cover those below. |

The box arrived fairly well packaged. |

Until I made a more permanent workspace, I decided to use it on top

of a Harbor Freight roll around tool box. The rolled edge on

top of the box was slick painted metal. I used some edge trim

to prevent the laser from sliding around. |

This material has a rubber type texture, and a metal clip inside.

I used heavy diagonal pliers to cut it to length. |

This worked great. The entire thing can be quickly moved in my

garage. |

The included water pump, to cool the laser during operation, is

sitting behind the laser enclosure. |

The 40 Watt tube is the width of the enclosure. If you later

wish to bump the tube power up to 50W-80W, simply buy the tube

online, buy a larger power supply, and add an extension to the end

of the enclosure. There's already a removable plate on the

side of the enclosure to accommodate this. |

The stock work area is rather small. The aluminum plate, and

blue colored plate around the work area, are quickly removed with a

few screws. |

I made a new work platform from a piece of scrap aluminum. The

"punk" spikes were purchased in bulk on Amazon. They hold up

the material being cut, to allow airflow underneath. This

makes for a cleaner cut, and less likely to create a fire. |

I used a lab jack under the new work platform. It has a nob

that can be turned to adjust the height of the platform. The

laser lens is a fixed focal length. This requires the material

to be the correct height from the laser. The lab jack makes

this a very quick and easy task. If you're always using 3mm

work or acrylic, the jack never needs to be adjusted after the

initial setup. |

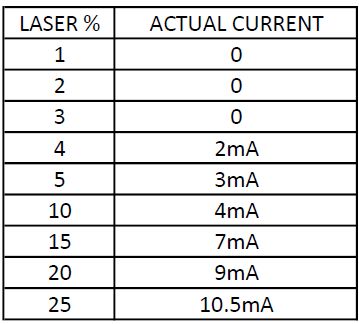

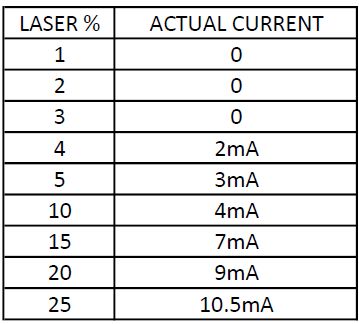

Not required, but highly recommended, a current meter. You can

mount it on the outside of the case, but I put mine inside the

enclosure next to the power supply. The netlore suggestion is to

keep the current below 10 mA to ensure the tube lives a long life.

Higher current equals a shorter lifespan. |

There are some very good videos of how to do a "Ramp Test" to

determine the correct work height. Afterwards, you can do a

power test to determine what the settings on the laser actual mean. |

At 9mA, the laser cuts 3mm (1/8") Baltic Birch plywood like butter.

It cuts 3mm acrylic panels just as cleanly. |

Digging through my electronic junque pile, I found a connector that

fits the jack on the power supply. This is where to connect

door switches to cut the laser power. |

The files for the 3D printed switch mounts are available for free on

ThingiVerse. I used 3M VHB tape to adhere the mounts to the

case. |

A simple lever switch provides a safety cut-off each time the door

is opened. The reason this is NEEDED is the laser is

invisible. If you reach inside the box while it's cutting, you

can easily get a hand in front of the beam between the mirrors.

You can get a significant burn at the least. If the beam

reflects from a watch face, or ring, you could lose an eye. |

The switch for the laser cutting area on the left, another switch

for the power supply area on the right. Note the push blocks

on the lids above that press the switches when the doors are closed. |

The stock exhaust fan works "ok". The air plenum inside

overhangs the work area. Dumb design. |

I cut it back using an angle grinder. This gives full use of

the available cutting area. Actual

available cutting area is now 325mm x 219.96mm, or 12.79" x 8.65". Works much better now. I may

still remove the plenum completely later. Not sure that it's even

needed. |

These are a few of things I made initially. The National Park

sign is 3D, which really makes it nice. The design is a

freebie on ThingiVerse. |

This is a simple drink coaster I made and sold on Etsy. |

I made a bunch of these, and some boxes for mini bottles of Fireball

Whiskey. They were great stocking stuffers for my extended

family. |

The design has no hardware. Just laser cut pieces, glued

together. Has a wooden hinge point. |

I bought a nice roll around tool box that doubles as a work table. |

The drawers are great, but it doesn't come with dividers. I

laser cut some boxes, and some holders for Dremel moto-tool bits. |

I made a batch of heart shaped boxes for Valentine's Day. Sold

these on eBay and Etsy. The curved section has many tiny

slits, creating a "living hinge". The plywood easily bends to

curved shapes with the many tiny cuts. |

I will be making a lot more projects from acrylic. This stuff

engraves and cuts beautifully. I experimented on a single

piece until I had the setting dialed in. The puck base was

part of a kit, that included one piece of acrylic. They want

you to buy more of their pre-cut pieces of clear acrylic. But

it is EASY to cut your own from a 12"x12" sheet. The base has

LEDs inside that change colors. Comes with a remote.

Looks a lot better in person. The kit is linked below. |